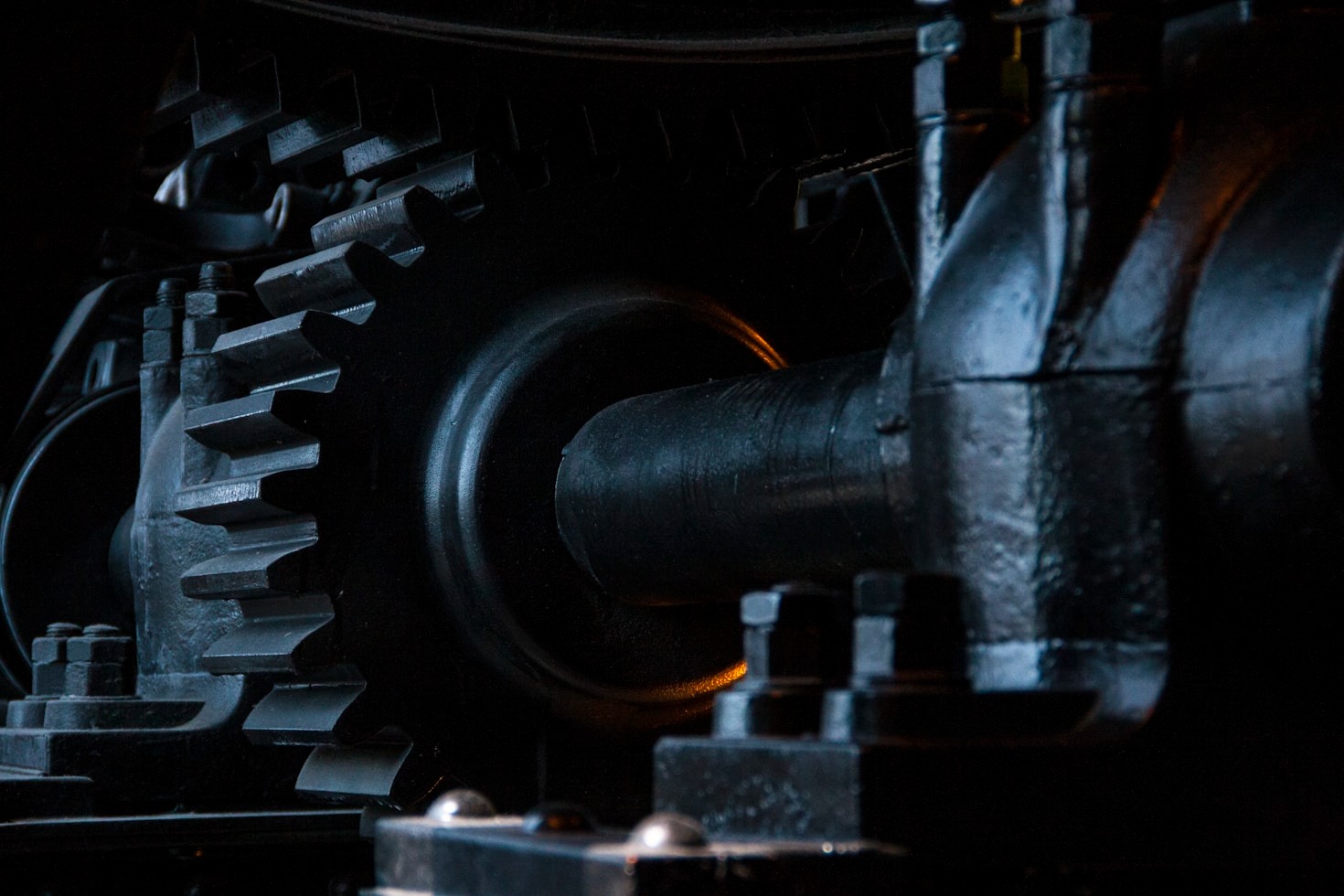

This week, at my site, we are conducting X-ray inspections of welded pipelines. This activity motivated me to write this article to highlight the importance of this practice and the need to maintain a safe distance during the process.

X-ray inspection of welded pipelines is an indispensable technique for ensuring quality and safety in various industries.

Why is X-Ray Inspection Crucial?

- Detection of Invisible Defects: X-rays allow the identification of internal defects in welds, such as cracks, porosity, or slag inclusions, which are not visible to the naked eye. These defects can compromise the strength and durability of the pipeline.

- Regulatory Compliance: Industrial regulations and international standards require the inspection and certification of welds to ensure they meet quality and safety standards. This not only ensures that structures can withstand operational pressures and conditions but also protects users and the environment from potential failures that could have catastrophic consequences. Additionally, regulatory compliance helps companies avoid legal penalties and maintain a reputation for reliability and safety in the market.

- Failure Prevention: Early detection of defects allows for repairs before a catastrophic failure occurs, preventing production interruptions and reducing long-term maintenance costs. For this reason, it is essential to request these services from specialized companies that have the technology and trained personnel to perform high-quality inspections. Specialized companies have the experience and necessary equipment to correctly identify and evaluate defects, providing detailed reports and precise solutions to ensure the integrity of welded structures.

The Importance of Maintaining a Safe Distance

The use of X-rays involves exposure to ionizing radiation, which can be harmful to health if not handled properly. Therefore, it is crucial to follow strict safety measures to protect workers and the public.

- Radiological Protection: Maintaining a safe distance and using appropriate physical barriers minimizes exposure to radiation. This is crucial to avoid harmful effects such as tissue damage and increased cancer risk.

- Signage and Access Restriction: Implementing warning signs, like the one shown in the image, is vital to alert people to the presence of radiation. It is also essential to restrict access to areas where X-ray inspections are being conducted. Work areas should be clearly marked with warning tape and visible signs indicating the presence of radiation. It is important that only authorized personnel, who have received proper training and are equipped with the necessary protective gear, have access to these areas. This not only protects the workers but also anyone who might be near the inspection site.

- Training and Protective Equipment: Workers must receive adequate training on the risks of radiation and the correct use of personal protective equipment (PPE), such as dosimeters and lead shields. Companies dedicated to X-ray inspection have highly qualified personnel to ensure high-quality work that is always focused on safety.

In Conclusion

X-ray inspection of welded pipelines is an indispensable technique for ensuring quality and safety in various industries. However, it is equally important to implement rigorous safety measures to protect workers and the community from radiation exposure. Combining effective inspection practices and solid safety protocols guarantees a safe work environment and reliable, efficient industrial operations.